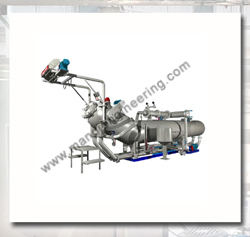

We Manoj Engineering are Leading Manufacturers, Suppliers, Exporters, Traders, Provider of hthp banana fibre dyeing machine . Banana fiber is a natural fiber derived from the stems of banana plants. It is gaining popularity as a sustainable and eco-friendly alternative to synthetic fibers. The fiber is extracted from the plant's pseudostem, which is then processed and spun into yarns for various applications, including textiles and paper products. Dyeing banana fiber involves the application of color to the fiber to achieve the desired shade. The dyeing process for banana fiber is similar to other natural fibers and can be done using different dye types such as natural dyes or synthetic dyes. High-temperature and high-pressure dyeing machines are commonly used in textile industries for dyeing various fibers, including natural fibers like cotton, silk, and wool. These machines provide controlled conditions of temperature and pressure to enhance dye absorption and fixation, resulting in vibrant and long-lasting color on the fibers. If there is a specific HTHP banana fiber dyeing machine developed after my knowledge cutoff, I apologize for not being able to provide information on that. I recommend conducting a more recent search or reaching out to textile machinery manufacturers or industry experts for the latest developments in this field.HTHP (High-Temperature High-Pressure) Fibre Dyeing Machine is a specialized equipment used in the textile industry for dyeing synthetic fibers, such as polyester, nylon, acrylic, and more. This machine is designed to handle the specific dyeing requirements of these fibers, which often necessitate higher temperatures and pressures compared to natural fibers like cotton.

The HTHP Fibre Dyeing Machine provides an enclosed dyeing environment where the fibers are subjected to elevated temperatures and pressures to facilitate the dyeing process. The machine employs a heating system to raise the temperature of the dye liquor and the fibers. It may use steam, electric heaters, or other heating methods to achieve the desired temperature range. The machine also incorporates a pressure system to generate and maintain the required high-pressure conditions during dyeing. This system can consist of a pressurized water supply, pneumatic components, or hydraulic systems. The HTHP Fibre Dyeing Machine ensures efficient dye penetration and uniform dye distribution through the use of a circulation system. This system typically includes pumps and nozzles that facilitate the movement of the dye liquor through the dyeing vessel. The machine features a control panel with various settings and controls to regulate parameters like temperature, pressure, dyeing time, and agitation speed. It allows operators to monitor and adjust these parameters throughout the dyeing process. HTHP Fibre Dyeing Machines incorporate safety measures to protect operators and prevent accidents. These features can include pressure relief valves, temperature sensors, emergency stop buttons, and interlock systems. The HTHP Fibre Dyeing Machine offers several advantages in the dyeing of synthetic fibers. The combination of high temperature and pressure ensures efficient dye absorption, resulting in vibrant and colorfast dyed fibers. It also reduces dyeing time, improving productivity for textile manufacturers. Additionally, the closed system minimizes environmental impact by preventing the release of dye and chemicals into the surroundings. We Manoj Engineering are deeply engaged in offering a wide array of hthp banana fibre dyeing machine to our valuable Clients located in Mumbai, Navi Mumbai, Thane, and all over India.