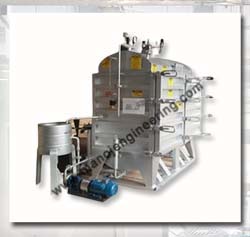

We Manoj Engineering are Leading Manufacturers, Suppliers, Exporters, Traders, Provider of jute yarn dyeing machine . A jute yarn dyeing machine is a specialized piece of equipment used in the textile industry to dye jute yarns. Jute is a natural fiber commonly used in the production of various products such as bags, ropes, carpets, and textiles. The dyeing machine is designed to apply color to the jute yarn by immersing it in a dye bath. It consists of a large cylindrical vessel, usually made of stainless steel, with various features and components to facilitate the dyeing process. Here are some key components and features you may find in a typical jute yarn dyeing machine The main part of the machine where the dyeing process takes place. It is filled with a suitable dye solution or chemical mixture for coloring the jute yarn. These are spindles or cones on which the jute yarn is wound. They hold the yarn and allow it to be immersed in the dye bath. The number of carriers can vary depending on the machine's capacity. To ensure uniform dyeing, the machine has a circulation system that facilitates the movement of the dye solution. It may include pumps, pipes, and nozzles that distribute the dye evenly throughout the dye bath. Most jute yarn dyeing machines are equipped with a heating system to control the temperature of the dye bath. Proper temperature control is crucial for achieving desired color fastness and dye absorption. This is the interface where the operator can set and monitor various parameters such as temperature, dyeing time, and speed of the machine. Modern machines may have advanced automation features for precise control and monitoring. Depending on the dyeing process and desired color, additional chemicals or auxiliaries may be required. The machine may have a provision to add these chemicals at specific stages of the dyeing process.

After the dyeing process is complete, the machine should have a system to drain the dye liquor from the dye bath. Proper drainage is essential for rinsing and subsequent processes. Safety is a crucial aspect of any industrial machine. Jute yarn dyeing machines may include safety features such as emergency stop buttons, temperature and pressure sensors, and alarms to ensure the well-being of the operator and prevent accidents. It's important to note that the specific design and features of jute yarn dyeing machines can vary among manufacturers and based on the scale of operations. Industrial dyeing machines often incorporate advanced technologies to enhance efficiency, reduce water and chemical consumption, and minimize environmental impact. A jute yarn dyeing machine is a specialized equipment used in the textile industry for dyeing jute yarns. Jute is a natural fiber derived from the jute plant, primarily grown in India and Bangladesh, and is widely used for making various products like sacks, bags, carpets, and ropes. The process of dyeing jute yarn involves immersing the yarn in a dye bath containing the desired colorant and chemicals to ensure proper fixation of the dye. The jute yarn dyeing machine facilitates this process by providing controlled conditions for dyeing, ensuring uniform coloration and efficient dye penetration.We Manoj Engineering are deeply engaged in offering a wide array of jute yarn dyeing machine to our valuable Clients located in Mumbai, Navi Mumbai, Thane, and all over India.